CDA SPRAYING SYSTEM IN AGRICULTURAL DRONES

Technological advances are revolutionizing many fields, and agriculture is no exception. One of the latest developments in this area is the CDA (Controlled Droplet Application) spraying system used in ABZ Innovation's L10 and L10 PRO agricultural spray drones. This innovative technology allows for precise and efficient application of crop protection products, bringing many benefits to farmers and the environment.

The secret to effective spraying lies in the even and targeted distribution of the liquid.

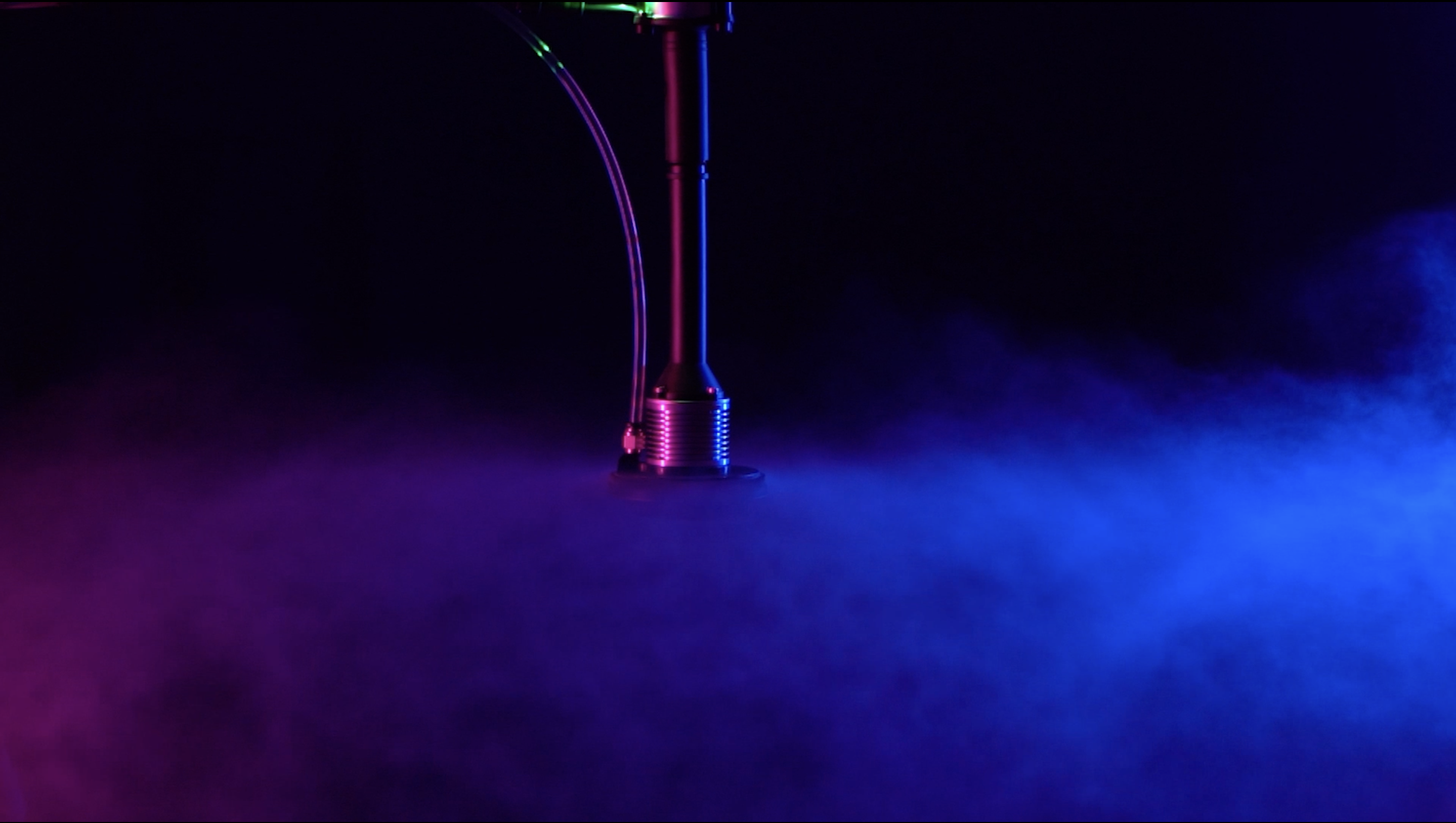

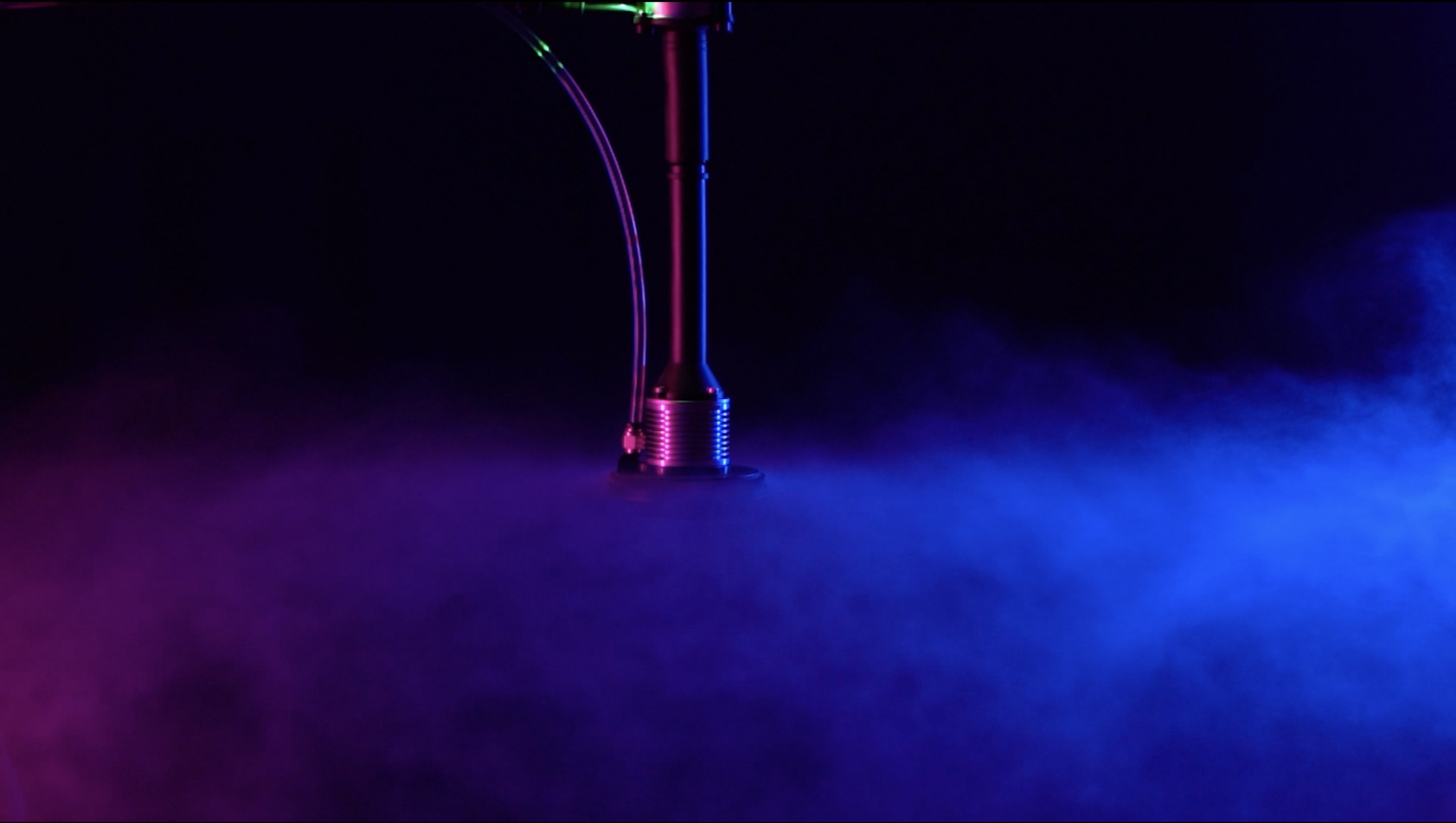

In CDA (Controlled Droplet Application) technology, with the power of a brushless motor, the spray liquid is fed at low pressure to a rotating disk. Through centrifugal force, the droplets break away from the edge maintaining a uniform size. The lack of dependence between flow rate setting and droplet size allows flexible control and setting of droplet size. This also gets rid of oversized and undersized droplets, which means no waste and no unnecessary contamination, because each droplet is the right size, so it doesn't run off the leaves and evaporate. With the force of the propeller air, the liquid is directed downward reaching the lower parts of the plant.

CDA application v Nozzle spraying

In contrast, most conventional spraying machines employ a hydraulic nozzle which involves breaking up spray liquid by squirting it under pressure through a hole. This application method is rather inefficient as it breaks up the spray liquid very unevenly and produces a very wide range of droplet sizes.

Very large and very small spray droplets are both wasteful - the large ones end up on the ground whereas the small ones drift wasting much of the spray and contaminating the environment. This inefficiency means that hydraulic nozzle sprayers have to use much more spray liquid than is actually necessary to do the job. To fetch, carry and spray this extra liquid costs time, effort and money for both the small farmer in the developing world carrying out most jobs manually or the large mechanised western farmer.

The waste and environmental contamination resulting from spraying pesticides through hydraulic nozzles is causing increasing world-wide concern. CDA offers a scientifically-proven solution that improves spraying efficiency, eliminates waste and safeguards the environment.

The efficiency of CDA enables the use of low and ultra-low volumes of spray liquid. This logistical advantage can be of critical importance in crop protection, allowing effective spraying programmes to be undertaken quickly in non-mechanised agriculture and greater spraying productivity in mechanised agriculture. Being able to apply pesticides accurately, quickly and cost - effectively when needed gives the opportunity of fully implementing Integrated Pest Management programmes, with reduced overall pesticide usage.

Performance of CDA TECHNOLOGY

L10 and L10Pro drones provide precise coverage thanks to intense airflow with CDA technology

- No pressure required

- Adjustable droplet size +/- 5%

- Suitable for organic farms

- Up to 95% less water

- Up to 60% less pesticides

- Further savings with precision spraying

- Flow rate: 4.8L/min

- Minimal spray drift

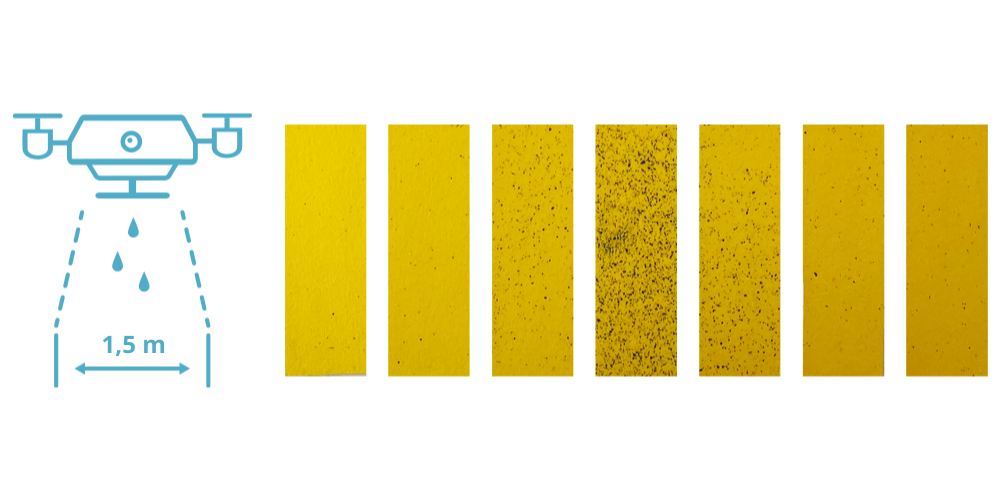

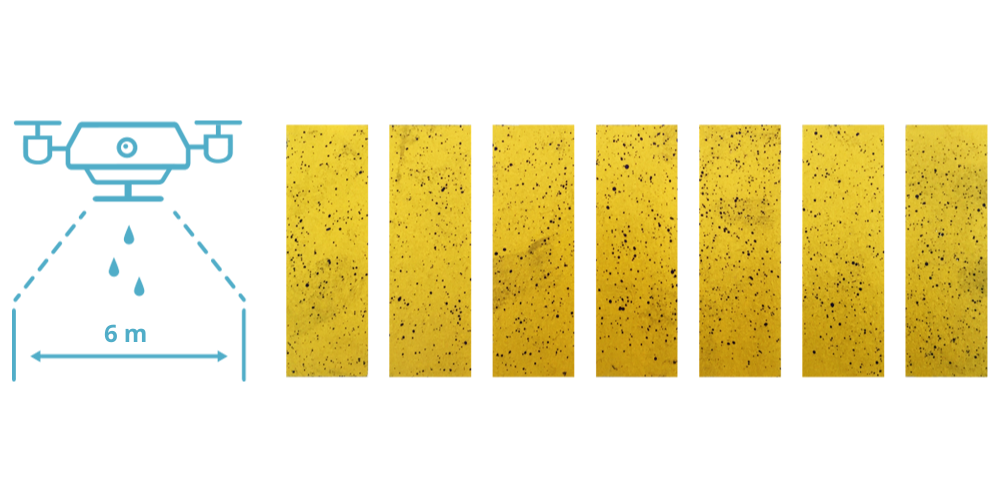

1.5 meter – 40 l/ha

6 meters – 12 l/ha

CDA (Controlled Droplet Application) technology offers a wide range of economical and environmental benefits which include:

Operational efficiencies:

- Cost savings due to reduced volume of spray

- Even droplet distribution and uniform droplet size produce better spraying results

- A considerably faster spraying operation

Increased productivity:

- Considerably less spray liquid is needed compared with conventional sprayers

- Consequently the amount of time and effort required are considerably reduced

- Hand-held sprayers incorporating CDA reduce physical effort as strenuous pumping is eliminated

Improved chemical efficacy:

- CDA technology improves target coverage and spray droplet retention

Safer Spraying:

Significantly reduced operator contamination risk during the spraying process:

- Operator errors due to fatigue are reduced as the process is less arduous than high volume nozzle spraying

- Fewer mixing and filling operations where operator contamination is most likely

Reduced Environmental Impact:

- Reduced chemical and water requirement

- Lower contamination of soil compared to nozzle spraying thanks to low-volume, targeted application