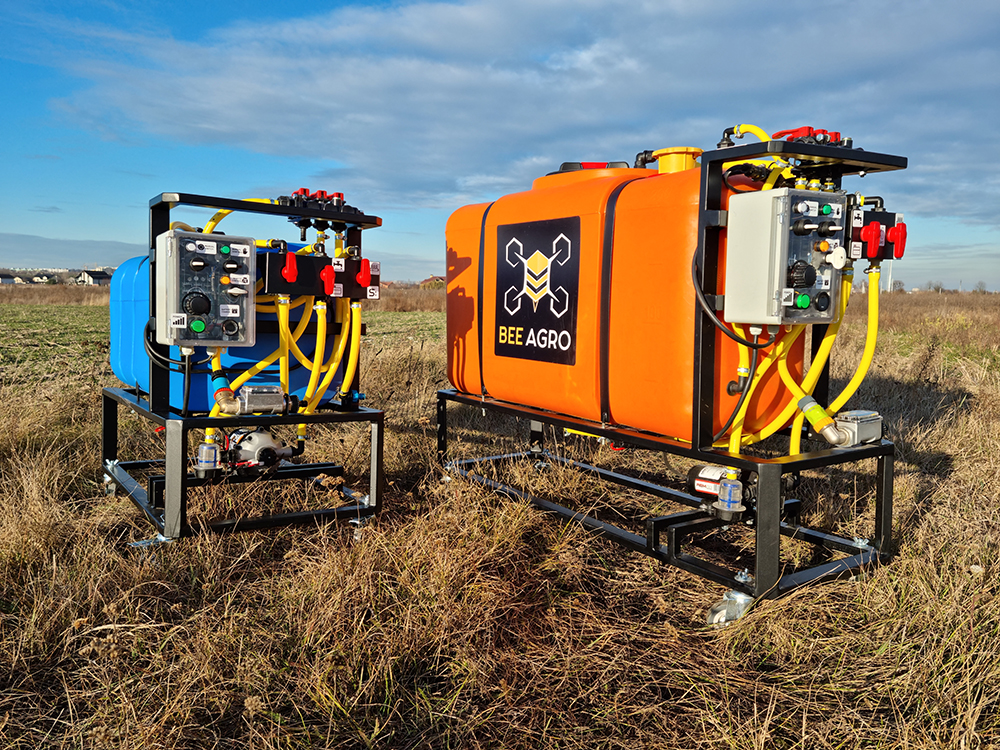

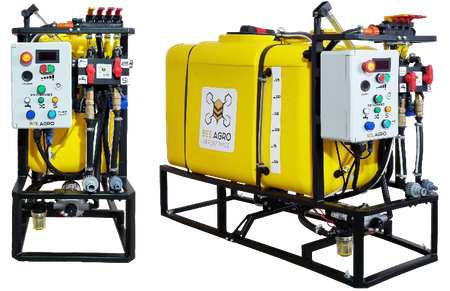

BeeAgro Mixers PROfessional 100/200/300 L mixing station

- Bee Agro mixers for agricultural drones

PROfessional Series is a professional solution with advanced functionality for experts in the field of agricultural drones. This series, which has all the functions of the basic EXP except for programmable automatic water pumping and dosing of ready-made solvent, is the basis for future development. Because the flexibility and adaptability of the microprocessor platform allows for easy modification according to market needs.

Advantages of Use

Uniformity and precision in mixing solvent ingredients

Minimization of human contact with toxic substances

Optimization of drone refilling time

Improvement of professionalism

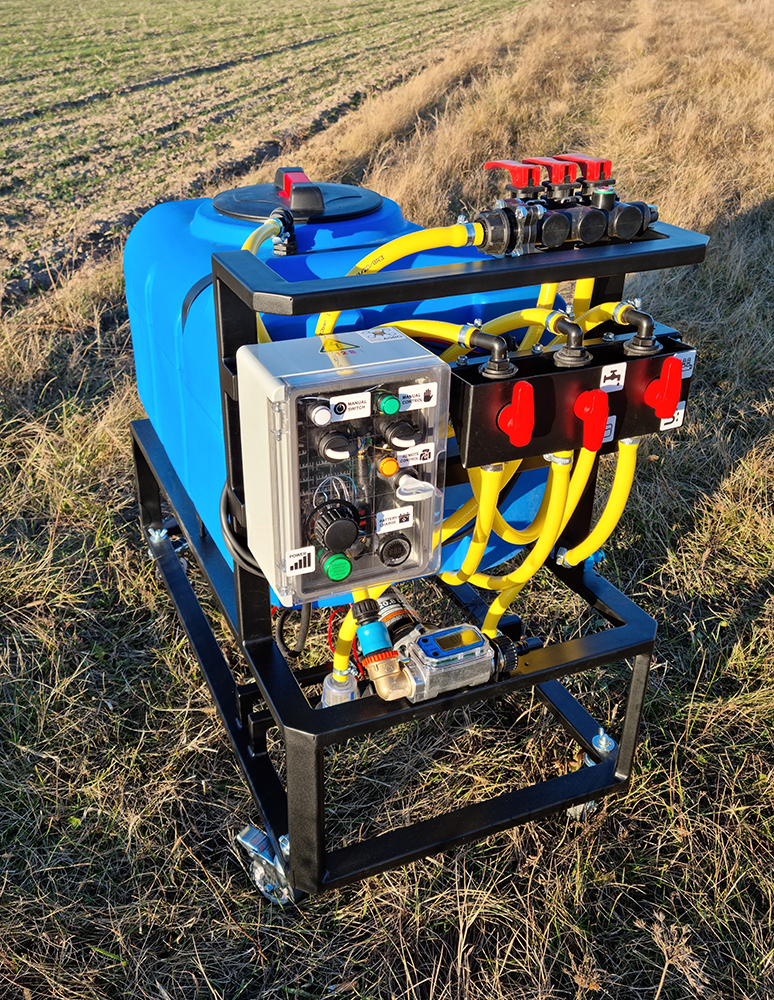

- Water meter

- Mixing system

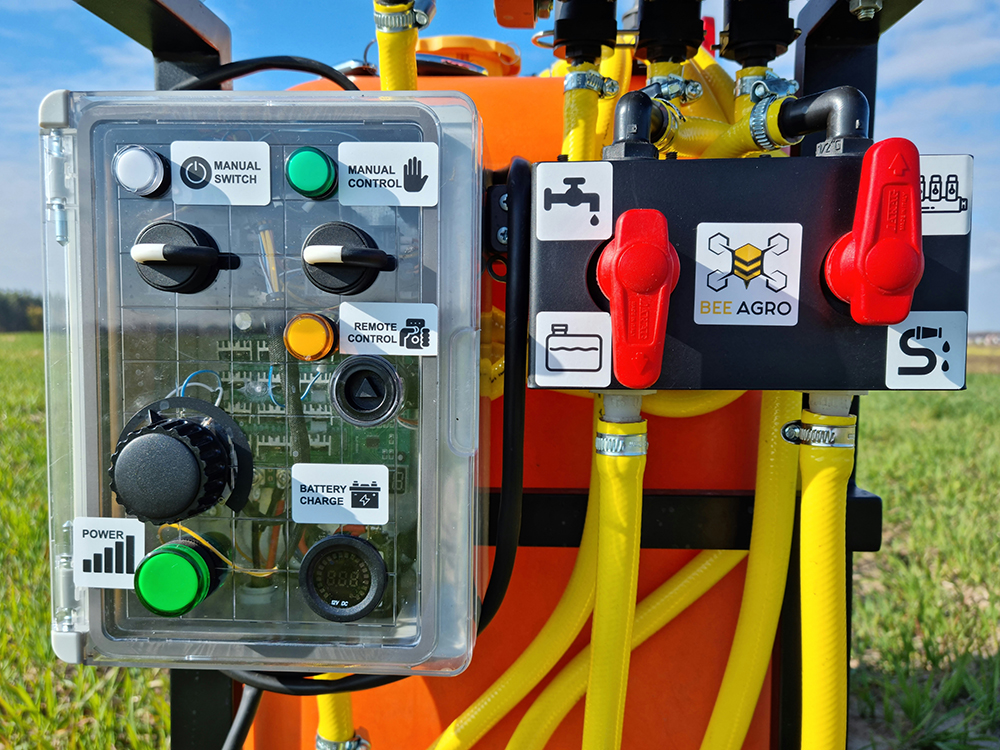

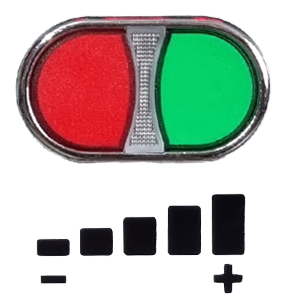

- Remote control, 2 pcs.

- Pump hose filter

- Bucket filter

- Float level indicator

- Battery power cable

- Rubber bracket, 4 pcs.

- Tank washing system

- Pump 26,5 l/min

- Tank washing system

- 220 V mains power supply

- Water cleaning filter

- Hose with connectors and filter, 20 m

- Refilling pistol

- Nozzle adapter

- Transport wheel, 4 pcs.

- Canister washing system

- Solvent dilution system

- Lighting

- Dispenser input

- Dispenser output

Design Features

The pump, pipes, tank, manifold, tap, etc. – the parts used in the construction – are produced by the world’s best manufacturers and are resistant to harsh environments and chemicals.

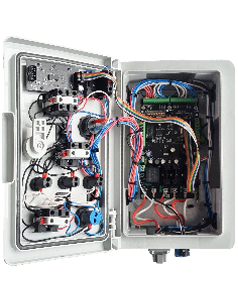

The control and management system is based on a microprocessor. This allows for managing all processes in real time, as well as for easy modification of the equipment composition according to the client's needs.

The 12 V power system is equipped with a charge control indicator, enabling field operation using batteries. Optionally, it is equipped with a 220 to 12 V power converter for generator operation.

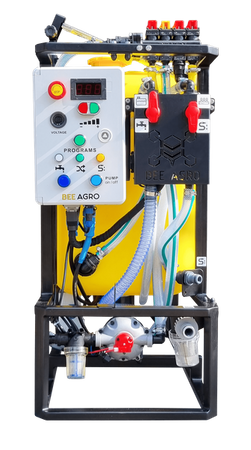

Precise control of pumping water from an external tank for solvent preparation. The PRO series employs pulse flow sensors.

The inline filters of the pump and the "intake" hose protect the equipment from abrasive materials and contaminants such as clay, sand, dirt, etc. This significantly extends the lifespan of the mixer and minimizes downtime.

Remote control allows a single operator or pilot to refill the drone right next to the UAV. This is standard for all types of mixing stations.

Refilling pistol – safety and convenience for the operator during the drone’s "pit stop". The high-pressure spray adapter serves as a drain for the mixer, drone, and other equipment after field work.

The basket-shaped mesh filter serves as a safeguard against debris and small particles entering the tank. It minimizes the risk of clogging the drone's injectors or sprayers.

The tank washing system cleans the interior walls of the tank from residual solvent, thereby facilitating the removal of operational residues after work. Optional for ECO.

The canister washing system allows for cleaning of residual substances, which facilitates the future container disposal process and minimizes the operator's contact with harmful substances.

The pump speed regulator allows control over the efficiency and quality of mixing, as well as controlling the foaming of substances that tend to foam.

Autonomous LED lighting for nighttime work – a folding telescopic pole with a lamp is installed on the mixer frame.

Playing with the engine speed regulator during operation ensures constant mixing of the solvent and reduces the risk of sedimentation of substances that tend to settle.