DRONES IN PHOTOVOLTAICS - INSPECTIONS OF PHOTOVOLTAIC INSTALLATIONS

Unmanned aerial vehicles are an excellent tool for inspecting solar installations because of their ability to quickly and accurately perform inspections. Traditional methods, such as manual inspections, require a lot of time and effort. For large solar installations, such a method is very labor-intensive and expensive. In contrast, professional drones equipped with thermal imaging cameras can scan a solar installation from the air, detecting potential problems such as overheated cells or damaged panels.

Second, drones allow for easier and safer inspections of installations, especially in hard-to-reach areas. Often they are placed on rooftops, at height, making inspections difficult. In such cases, traditional inspection methods require the use of lifts or ladders, increasing the risk of accidents. Drones, on the other hand, can scan solar installations from the air without exposing workers to danger. In addition, their use for solar panel inspections can also increase the accuracy and efficiency of inspections, as drone cameras can provide accurate and detailed images of solar panels.

One of the most important aspects of using drones to inspect solar panels is saving time and money. Standard methods require a lot of time and labor, which translates into higher costs. Using UAVs will help reduce these costs, as well as provide faster and more accurate results.

What's more, using drones to inspect solar panels is also more environmentally friendly. Traditional methods require the use of vehicles or machines that use fossil fuel and can contribute to greenhouse gas emissions. The use of drones is more environmentally friendly because they are powered by batteries and do not emit pollutants.

How it works.

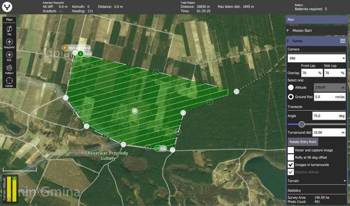

Aerial inspection of a solar power plant is a service that provides a deep, complete view of a solar power plant's condition. To do this, a drone performs an inspection flight over the power plant, filming and taking photos in visible light and thermal infrared, documenting every point of the power plant in multiple images. AI-based algorithms will then detect and identify any possible technical problems and faults, such as damaged diodes, shaded areas, cracks, holes, faulty connections, reversed polarities, dirt and hot spots. All such problems will be annotated with the exact location (down to the panel and cell number), and a description of the nature of the problem.

After the review, you will receive a technical report. And in it you will get an orthophotomap of the installation, a detailed list of the problems found including information on the type of problem (e.g., a faulty diode), information on the location of the problem, as well as potential energy losses. It is recommended to perform such inspections first after the installation is built, and then regularly 2 times a year, or as soon as a problem is suspected.

What do you gain?

With UAV inspection, you can

- Increase the efficiency of your investment

- Control the quality of workmanship and compliance with the original design during the commissioning of a new solar power plant

- Prevent kWh losses and performance degradation and performance deterioration during the operational period

- Precisely locate technical problems

- Efficiently and accurately track the technical condition of the power plant during its operation and

- Maintain its maximum efficiency

- Obtain information on how much energy in kWh is lost due to an existing technical problem

- Save time in diagnosing and locating power plant problems